-

Broj sadržaja

40216 -

Na DiyAudio.rs od

-

Broj dana (pobeda)

594

Content Type

Profiles

Forum

Blog

Kalendar

Sve objavljeno od Zen Mod

-

ih da sam znao ranije da njima dvoici napravim poseban forum mi pemzioneri duzivamo lagano uz pivce a nji dvoica da derneče uz dacovi (jos kad bi Mikum znao kako da napravi I/V konverziju kosher, da cuje kako onda svira; al da ne lajem, ne'm vreme da to pravim)

-

sdce brat Nixie da te banuje for good msm, drzi guju u njedrima ....... on te podrzava i sokoli a ti tako da ne pricam o tome da ja sve na daskama pravim, pozderacama

-

-

ko se sve danas zove gospoda, ja radosan sto sam seljak

-

oto sustanje ....... bice da nisam dobro odstampo PCM63 msm, prvo se zajebunio pa odstampo 3 crowns, pa moro da brisem

-

kao i svake godine, na planinu nosim lapatopa (sos mouse, ne moze da se radi kako treba bez njega) pa kad nisam u setnji i ne citam, onda se malo crta pa se malo crtaju pcbs u ladovinu na terasi uz ladno pivo pa pomislim da je dole u ravnici bar 5C vise ..... ihaj

-

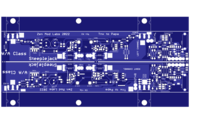

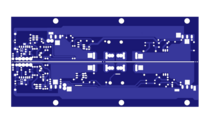

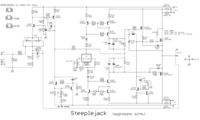

za one koj nemaju para za Tokin SIT......... Steeplejack - ide Schade verzija za one koje interesuje striktno pinpoint machine, ide cista MOS verzija kad ce se moci cuti ........ nempojma negde druga polovina avg. pcbs da se verifikuju i izvrse finalna merenja, al' kol'ko ce se zadrzi na T-Bed, zavisi od inspiracije u medjuvremenu ce pojede B. J2 za dorucak ..... iako zvuce isto

-

ma sva zvuce isto

-

cekaj, tek se zaukavam

-

-

to je bilo jasno jos od prvog vagona

-

problem je kad je ti napravis, odes ostavljajuci sve kako treba a onda Stranka dovede svoje strucnjake

-

sto rece jedan ''jbo sladoled ako nije kilo"

-

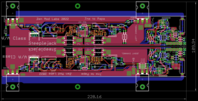

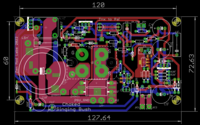

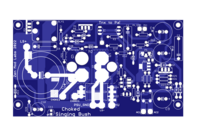

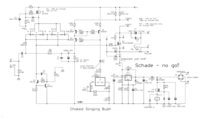

Choked Singing Bush ..... special one for Purists and Masochists

Zen Mod je odgovorio/la Zen Mod's temus u Solid State

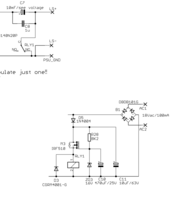

predmetno napajanje sam onomad dobio od naseg ortaka Davor-a koliko se secam koristeno je u tehnici mobilne primopredaje -

Choked Singing Bush ..... special one for Purists and Masochists

temu je objavio/la Zen Mod u Solid State

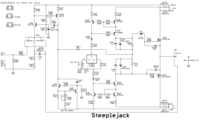

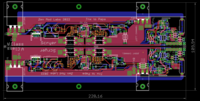

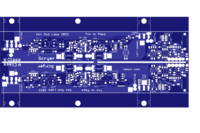

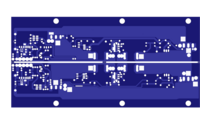

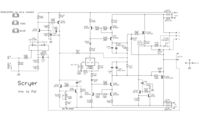

https://www.diyaudio.com/community/threads/choked-singing-bush-special-one-for-purists-and-masochists.388480/ OK, this one long in making I mean - have pcb files and everything for some time, basic functions confirmed but - as is my nature - never working by plan Anyway - why Purists and Masochists? List of reasons: 1. you really need properly made high quality choke; 100mH, no more than 0R5 winding resistance, declared for 3A5dc (big Tokin) or 2A5dc (small Tokin) 2. PSU - bummer - heavy filtration; CLC, or C then cap multiplier followed with heacy C cell, or fat switcher ..... most likely also followed (by choice or necessity) with some sort of high-pass filter and followed with fat C cell 3. this time ( even if evidently intended as option) - no Schade Mos Puck; simply too high Rout of part itself (even if normally or even heavy Schaded), resulting in uberfunny transfer function and THD way too high; now - with all my crummy chokes (yes, Plethora of them but all crummy) that's the situation; there is a possibility that Schaded option is viable and worthy if adequate quality choke is used, but that I can't confirm, nor I intend to purchase it, in any way or arrangement 4. looking at all above - simply - cost; you gain something with lesser volts involved (vs. say "regular" Singing Bush) thus lesser heat and lesser Donut and lesser voltage caps and lesser Aluminum in sinks...... but then main choke, PSU choke, yadayada.... 5. yes, OPT is an option, for both shown iteration ( Big Tokin, small Tokin), don't have it, easy to try if you have one; same conditions as with choke - do not even try with cheaply made Iron there are few more reasons, worthy of this list, but I'm lazy to think now ..... Anyway, usual set of introductory eye-pleasing files: -

ovo